A concrete mixer is a device that combines cement, aggregate such as sand or gravel, and water to form concrete. A typical concrete mixer uses a REVOLVING DRUM to mix the components.

FACTORS AFFECTING SELECTION OF MIXER

- LOCATION of the construction site (distance from the batching plant)

- AMOUNT of concrete needed

- CONSTRUCTION SCHEDULE (volume of concrete needed per hour)

- COST (The allocated budget)

- QUALITY of the concrete produced

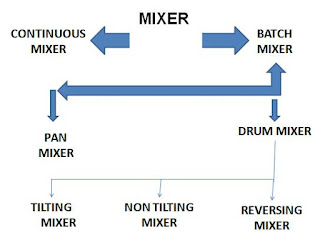

Types of Mixers

There are two main types of mixers used:

1.batch mixers and

2.continuous mixers.

Batch mixers are the most common.

2.continuous mixers.

Batch mixers are the most common.

Continuous Mixer

- Continuous type mixer produces concrete at a constant rate. In this type, the constituents are continuously entered at one end as the fresh concrete exits the other end.

- They are usually non-tilting drums with screw-type blades rotating in the middle of the drum.

- Two main types of batch mixer can be distinguished by the orientation of the axis of rotation:

2.inclined (drum mixers) or vertical (pan mixers).

The drum mixers have a drum, with fixed blades, rotating around its axis, while the pan mixers may have either the blades or the pan rotating around the axis.

Types of Drum Mixers

- Non-tilting drum mixer.

- Reversing drum mixer.

- Tilting drum mixer.

The non-tilting drum mixer implies that the orientation of the drum is fixed. The materials are added at one end and discharged at the other.

| X-Section of a Non Tilting Mixer |

|

| X-Section of a Truck Mixer |

- First truck mixer was invented in 1916.

- The reversing drum is similar to the non-tilting mixer except that the same opening is used to add the constituents and to discharge concrete.

- The drum rotates in one direction for mixing and in the opposite direction for discharging the concrete.

- Trucks weigh 20,000 pounds (9,100 kg) to 30,000 pounds (14,000 kg),

- Can carry roughly 40,000 pounds (18,000 kg) of concrete although many varying sizes of Mixer Truck are currently in use.

- Typically the speed for mixing is 1.57 rad/s (15 rpm), while the transport of pre-mixed concrete uses only 0.2 rad/s (2 rpm) to0.6 rad/s (6 rpm).

- Rear discharge truck mixers

- Front discharge truck mixers

"Rear discharge" trucks require both a driver and a "chute man" to guide the truck and chute back and forth to place concrete in the manner suitable to the contractor.

|

| Rear Discharge Truck |

| Front Discharge Truck |

Tilting mixer

- In this type of mixer axis of the drum does not remain horizontal.

- The position of drum axis for different operations i.e. feeding, mixing and discharge is different.

| Cross Section of a Tilting Mixer |

Pan Mixer

Components of a pan mixer are,

- Pan

- Shaft

- Scraper